Auxiliary tool

Instructional video

Introduction topic

Training hours

Tools

Familiarize yourself with over 60 tools

Cleaning tools

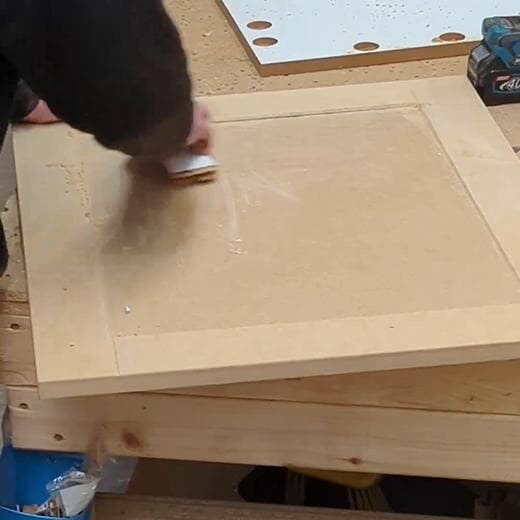

Preparation tools

Preparation tools

Cutting tools

Cutting tools

Installation tools

Installation tools

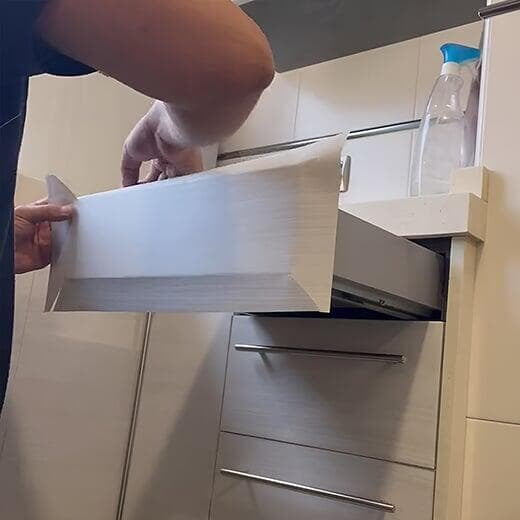

Auxiliary tools

Auxiliary tools

Installation stages

Understanding the different installation stages

Taking measurements

Correct measurement techniques and required margin amounts

Model characteristics

Characteristics of each model, its design nature, and grain direction

Auxiliary machines

Types of machines in cutting, installation, and reducing waste and costs

Pre-installation stages

Preparation and treatment

Types of surfaces

Installable and non-installable surfaces

Repairs

Methods for repairing and treating elements before installation

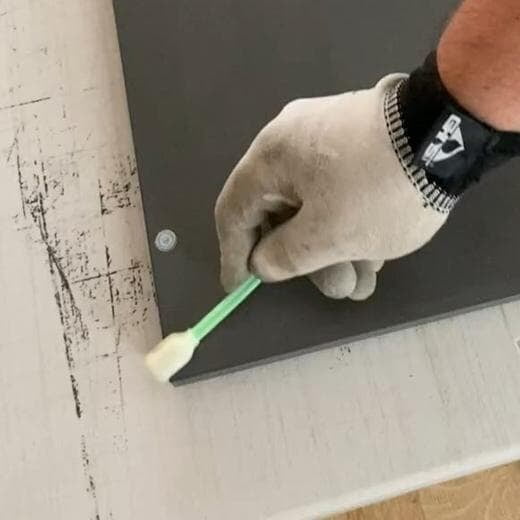

Removing impurities

Tools and materials for removing impurities and dirt

Adhesion boosters

How to use adhesive boosters and their placement

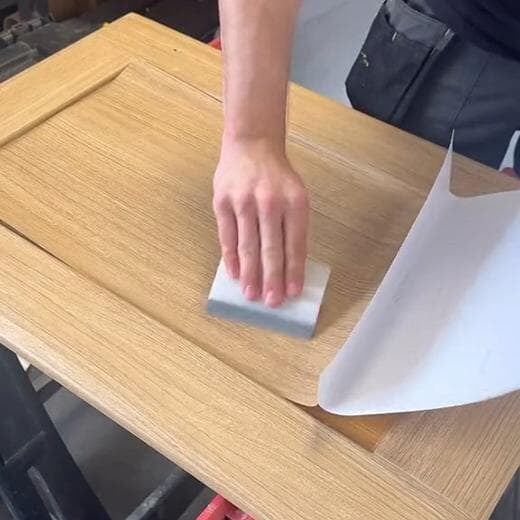

Material application

Methods for laying out the material and air release

Heating

Heating, expansion, and contraction processes

Installation skills

Angles

Skills for handling right angles and rounded corners

Edges

Skills for handling straight and curved edges

Element intersections

Skills for handling the intersection of two elements

Curves

Skills for working with flat and curved surfaces

Cutting

Professional cutting skills and auxiliary tools

Finishes

Learn professional finishing techniques