What we do

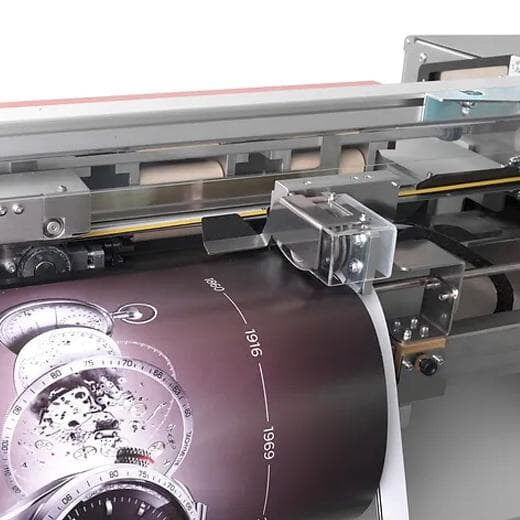

Roll-to-roll printer

Roll-to-roll printer

These printers are designed for printing roll materials, such as canvas, wallpaper, banners, vinyl, stickers, and blackouts. They use eco-friendly inks, suitable for both indoor and outdoor printing.

These printers are designed for printing roll materials, such as canvas, wallpaper, banners, vinyl, stickers, and blackouts. They use eco-friendly inks, suitable for both indoor and outdoor printing.

Flatbed printer

Flatbed printer

UV printing technology is designed for solid boards, such as acrylic, cladding, wood, glass, and Forex. It uses UV-curing inks to ensure color stability.

Digital cutting

Digital cutting

TA digital machine with specialized sensors for cutting printed and unprinted materials with high precision. It can handle both solid and flexible materials, such as fabrics, leather, cardboard, and wood.

TA digital machine with specialized sensors for cutting printed and unprinted materials with high precision. It can handle both solid and flexible materials, such as fabrics, leather, cardboard, and wood.

CNC cutting

CNC cutting

he CNC machine is used for cutting and engraving wood, acrylic, cladding, and other materials. It is suitable for furniture and interior decor production, allowing for complex designs and providing high precision in work.

he CNC machine is used for cutting and engraving wood, acrylic, cladding, and other materials. It is suitable for furniture and interior decor production, allowing for complex designs and providing high precision in work.

Lamination packaging

Lamination packaging

This machine is used to laminate prints with a transparent protective layer. This layer provides extra protection from the elements and enhances the elegance, extending the lifespan of the prints.

This machine is used to laminate prints with a transparent protective layer. This layer provides extra protection from the elements and enhances the elegance, extending the lifespan of the prints.

Roll cutting machine

Roll cutting machine

This machine is designed for cutting materials that require high precision, such as wallpaper. It is equipped with sensors that ensure edge alignment, providing perfect and consistent results in the work.

This machine is designed for cutting materials that require high precision, such as wallpaper. It is equipped with sensors that ensure edge alignment, providing perfect and consistent results in the work.

Our work steps

We follow four simple steps to ensure a decor experience that matches your taste and meets your needs, making you more satisfied and comfortable! This process will make you stand out from the rest.

Visit and discussion

Visit and discussion

We start with a visit from a trained expert to your office for a comprehensive consultation. We carefully listen to your requirements and ideas, considering the available options and what you wish to implement. Our goal is to accurately understand your taste and transform it into a reality that reflects your personality and style.

Planning and design

Planning and design

We use modern techniques and exceptional expertise in design to offer multiple models that embody your ideas. We ensure that the models reflect your personal taste and meet your desires. We are ready to make any adjustments you request to ensure complete satisfaction with the final design and provide a unique experience.

Printing and manufacturing

Printing and manufacturing

After completing the design, we send it to our workshops to begin production. We use the best materials and the latest technologies to ensure high quality. We apply precise standards to guarantee a final product that reflects the required details and fully meets your expectations.

Installation and delivery

Installation and delivery

We deliver and install the product on time and at the specified location with precision, adhering to schedules. We ensure that the space and surroundings are protected from any damage during installation. We provide exceptional installation services, making the space ready for use immediately upon completion, with no trace of the work left behind.

With them, we work

With them, we work